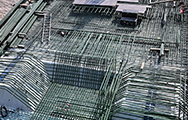

Q-Coat Product Range

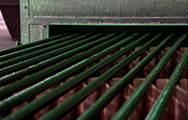

Epoxy Coated Rebar ranging in diameter from 8mm to 40mm

Length : 12 Meter

International Standard of FBECR vis-a-vis Q-coat

| Parameter | ASTM A775:2007 |

BS ISO 14654:1999 |

Q-coat (Average) |

|---|---|---|---|

| Bar Anchor Profile | 1.5-4.0 mils | 1.96-2.75 mils | 2.0-4.0 mils |

| Coating Thickness | 7-12 mils [8-16mm] 7-16 [18-40mm] |

7-12 mils | 10-12 mils (250-300 Microns) |

| Coating Holidays | 3 holidays/m(max) | 4 holidays/m(max) | 3 holidays/m |

| Coating Flexibility | 180 deg. bent using 8D | 180 deg. bent using 4D&6D | Complying with both standards |

| Cathodic Disbondment Test | Not Applicable | Average Disbondment Radius of Three Coated Steel Reinforcing bars shall not exceed 2mm | Average Disbondment Radius of Three Coated Steel Reinforcing bars shall not exceed 2mm-4mm |

| Bont strength with the concrete | Shall not be less than 85% off the uncoated bars | Shall not be less than 85% off the uncoated bars | Improved with 20 – 30% more rib height & Rib Area |

Quality Assurance :

At Q-Coat we are committed to achieve and maintain the highest standards of quality in all areas of operation by in process quality tests such as :

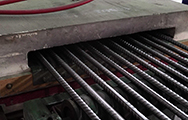

- Oil Contamination Test

- Near-White Blast Cleaning using SSPC-SP10

- Backside Contamination Tape Test

- Copper Sulfate Test

- Surface Profle Measurement

- Bar surface temperature using non- sulfurous temperature- sensitive crayons and infrared temperature gauge

- Coating holidays using inline and hand held holidays detector

- Coating Thickness

- Coating Flexibility by 180° Bend Test

Epoxy coated rebar is tested for following quality parameters :

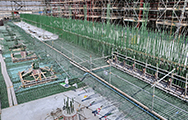

The technical expertise of Q-Coat in Fusion Bonded Epoxy Coating is reflected in its product quality with

recommendations received from numerous authorities and companies such as KAHRAMAA (Qatar General Electricity & Water), QAFCO (Qatar Fertilizer Company) and ISO 9001:2015 Quality Management system.