With the aim of promoting the usage of epoxy coated rebar in Qatar and GCC environment, a technical seminar was held by Qatar Metal Coating Company on 26/05/2014 at Grand Hyatt, Doha.

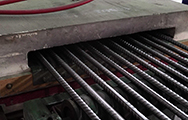

The seminar was about the protection of concrete structures against corrosion by using epoxy coated rebar, as a time tested solution for concrete corrosion, due to tough climate conditions in the Arabian Gulf.

Researchers from USA, KSA were invited. They spoke about their experiences and the results of the studies they conducted about using epoxy coated rebar, and they presented papers on the corrosion of steel in concrete, and how to protect it by using epoxy-coated reinforcing steel, being the most commonly used corrosion protection system in the GCC countries and in North America. The seminar also dealt with all technical queries about the product.

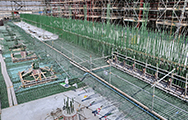

Dr.David McDonald, Managing Director of the US-based Epoxy Interest Group of CRSI, during his presentation, said: “The use of ECR in North America is very popular. The product was used in over 80,000 bridge decks (2013 NBI) covering over 89,000,000 sqm. McDonald said that apart from North America, the ECR is also the most widely used corrosion protection system in Japan, China, Middle East and India, where developers use it in many marine piers and other structures. Referring to the findings of forty years of research, he said: “The field performance of the product has been excellent both in marine and deicing salt exposure.”

Dr. Paul Donald Krauss from WJE, USA speaking about cost effectiveness of using ECR said that, ECR is the best solution compare to other options available in market as it involves low maintenance cost.

Dr. Ahmad S. Al-Gahtani from King Faud University of Petroleum and Minerals speaking about performance of ECR under high chloride and elevated temperature of GCC said that many researches in SAUDI proved that ECR is the perfect solution for gulf environment. He showed lot of ongoing research on ECR in Saudi and UAE.

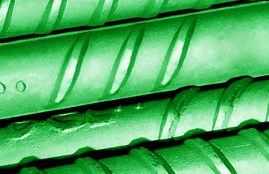

Dr. Matt O’Reilly from Kansas University speaking about bond strength of ECR with concrete said that, use of epoxy-coated reinforcement (ECR) in structural applications is common in the United States and elsewhere; however, the impact of epoxy coatings on the bond between reinforcement and concrete must be taken into consideration during design. Epoxy decreases the friction between reinforcement and concrete, decreasing the bond strength of the bar. Factors such as coating thickness, bar size, and deformation pattern all impact the degree to which an epoxy coating affects bond strength.

ASTM A775, A934, and A1055 state that an epoxy-coated bar tested in a beam-end specimen (ASTM A944) must have at least 85% of the pullout force of an uncoated bar from the same heat. This translates into bond strengths in full-scale beams equal to 70 to 85% of the values achieved by uncoated bars. Design codes take this behavior into account by requiring that the development and splice lengths of epoxy-coated bars be increased by 20 to 50 percent compared to those for uncoated bars.

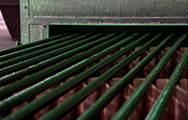

Ali bin Hassan al Muraikhi, Managing Director and General Manager of Q-Coat declared that the company presents practical and economical solutions for the protection of Concrete structure against corrosion, by providing the high quality epoxy coated rebar, which is the most effective protection means, especially in the GCC corrosive environment.

“Our responsibility is to contribute towards the sustainable growth of the construction industry by providing cost effective solutions to the corrosion problem. While this is a call for a sustained effort to improve the awareness on the benefits of using epoxy coated rebar, we are optimistic that our joint efforts would facilitate us in emerging successful in our endeavour.”, Muraikhi added.

Muraikhi pointed out that a research program was initiated last year in collaboration with Qatar University to conduct “Long Term Field and Laboratory Exposure Study”, in order to evaluate the actual performance of epoxy coated rebar and address the corrosion challenges in GCC severe environment subjected to high temperature, high humidity and salinity of sea. The outcome of this research will be presented to all stakeholders including Government and industrial bodies such as QP and its subsidiaries.